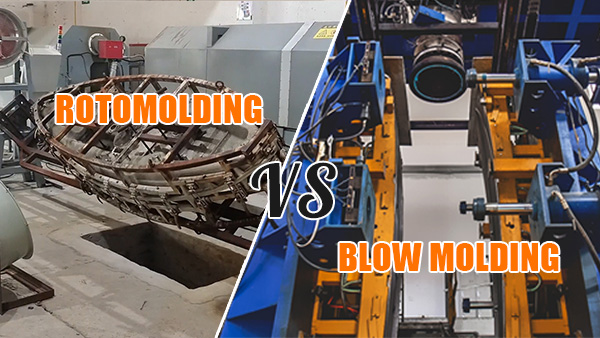

There are many different ways to manufacture kayaks, and each has its benefits and drawbacks. Rotomolding and blow molding are two of the most popular methods, but which is better?

Here, we’ll take a look at the pros and cons of each to help you decide which the best option for your business is.

Rotomolding

The rotomolding process is a manufacturing technique that is well-suited for producing kayaks. In rotomolding, a powdery resin is placed into a mold, and the mold is then heated until the resin melts.

The molten resin is then allowed to cool and harden, and the kayak is then removed from the mold. Rotomolding offers several advantages for kayak manufacturing.

- § First, it allows for complex shapes to be created. This is important for kayaks because they need to be aerodynamic and have a sleek design.

- § Second, rotomolding produces a kayak that is very durable and sturdy. This is essential because kayaks need to be able to withstand rough waters and constant use.

- § Finally, rotomolding is a relatively efficient and cost-effective manufacturing process. This makes it an attractive option for companies that are looking to produce high-quality kayaks at a reasonable price.

Blow Molding

Kayaks are traditionally made from rotomolded polyethylene, but in recent years, Blow Molding has become a popular alternative. Blow Molding is a manufacturing process that involves inflating a hot tube of molten plastic until it takes the shape of a mold.

This method is faster and more precise than rotomolding, and it produces a kayak that is lighter and stronger.

While Blow Molding typically costs more than rotomolding, many kayak manufacturers feel that the benefits outweigh the extra expense. As a result, Blow Molding is becoming an increasingly popular choice for kayak production.

Rotomolding Vs Blow Molding – Which Is Better For Kayak Manufacturing?

The debate between rotomolding and blow molding is one that has been around for quite some time. Each process has its own advantages and disadvantages, and there is no clear consensus on which is the better option for kayak manufacturing.

In this article, we will take a closer look at both processes in order to help you make a more informed decision about which one is right for your business.

Rotomolding is a process that involves the use of heat and pressure to mold plastic into the desired shape. This method is typically used for creating large, complex shapes that would be difficult to create using other methods.

One of the major advantages of rotomolding is that it can be used to create kayaks with very intricate designs. Additionally, rotomolded kayaks tend to be very strong and durable, making them ideal for use in rough waters.

The main disadvantage of rotomolding is that it is a relatively slow process. Additionally, rotomolded kayaks can be quite expensive to produce, due to the high cost of the equipment required.

Blow molding is a much faster process than rotomolding, and it can be used to create kayaks with simple designs. However, blow molded kayaks are not as strong and durable as rotomolded kayaks, and they are also more likely to leak.

So, which manufacturing process is right for you? The answer depends on a number of factors, including the type of kayak you plan on manufacturing, your budget, and your desired production speed.

If you are looking to create a high-quality kayak with a complex design, rotomolding is likely your best option. However, if you need to produce kayaks quickly and cheaply, blow molding may be the better choice.

No matter which manufacturing process you choose, it is important to work with a reputable kayak manufacturer that has experience in both methods. This will ensure that your kayaks are made to the highest possible standards and that you are getting the best value for your money.

Pros And Cons Of Rotomolding And Blow Molding!

The two main methods for manufacturing kayaks are rotomolding and blow molding. Here are the pros and cons of each to help you decide which the best option for your business is:

Rotomolding

Pros:

- Allows for complex shapes to be created

- Produces a kayak that is very durable and sturdy

- Is a relatively efficient and cost-effective manufacturing process

Cons:

- The rotomolding process is slow and can be time-consuming

Blow Molding

Pros:

- Is a faster and more precise manufacturing process

- Produces a kayak that is lighter and stronger

- Is becoming an increasingly popular choice for kayak production

Cons:

- Blow molding typically costs more than rotomolding

- The Blow molding process is not as well-suited for creating complex shapes

Conclusion

Blow molding has many benefits over rotomolding. It is faster, easier to automate, and results in a higher-quality product. If you are looking for a manufacturing process that will produce a top-quality kayak, blow molding is the way to go.

However, if you are on a tight budget, rotomolding may be the better option for you. Whatever you decide, make sure to weigh the pros and cons of each manufacturing process before making your final decision. Hope this helped!