What Material To Manufacture A Kayak

Think about gliding over a calm lake or battling the rough waters. Your kayak isn’t just a boat; it’s a carefully built ally for these moments. Ever wonder what makes up this crucial piece of equipment? Polyethylene is the key material used in kayak making. Within this material, we find different types: high-density polyethylene (HDPE), medium-density polyethylene (MDPE), and low-density polyethylene (LDPE). These types are more than fancy words. They are key to how your kayak performs, survives, and moves. The choice of material is a balance of science and art. It deeply affects your time on the water.

Key Takeaways

- Understanding the differences between HDPE, MDPE, and LDPE is critical for assessing kayak durability and performance.

- The grade of polyethylene used influences the kayak’s strength, rigidity, puncture resistance, abrasion resistance, and ability to retain its shape.

- HDPE is renowned for its robust performance in extreme kayaking conditions and resilience to high temperatures.

- MDPE kayaks offer a balance in cost and function for everyday use.

- LDPE kayaks are affordable but consider performance and ethical manufacturing issues.

- Polyethylene’s role in making kayaks is crucial for a great paddling experience. Think carefully when choosing a kayak.

Kayak Materials 101

Understanding Kayak Materials and Construction

As a kayak manufacturer, it’s key to know what your vessel is made of. Different kayaks work best for different activities. This depends largely on their materials and how they’re built. Let’s look closer at these aspects.

Choosing the Right Material: A Manufacturer’s Dilemma

The first step in making a kayak is very important. It greatly affects the kayak’s strength and what it can do. Finding the best material is like solving a tough puzzle. Makers need to think about what kayakers want. They also have to match materials to performance goals.

The Role of Polyethylene in Kayak Building

Polyethylene is very important in making kayaks. But, not every polyethylene is the same. There are many types, from HDPE to LDPE. Each offers different benefits. Makers need to choose wisely to meet kayakers’ needs.

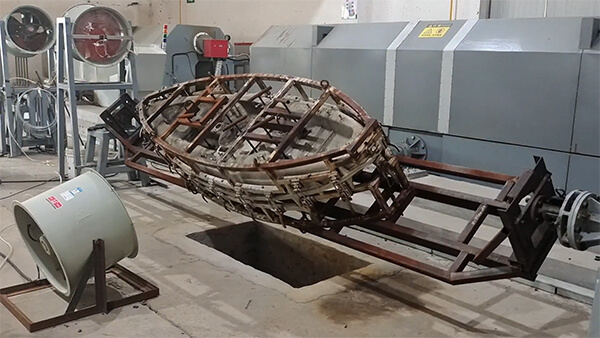

Insights into Rotational Molding and Kayak Durability

Rotational molding for kayaks needs great care, especially with the temperature. This method helps make kayaks that last long. Makers use this to ensure kayaks can handle many adventures.

| Polyethylene Grade | Properties | Best Use Scenario | Rotational Molding Considerations |

|---|---|---|---|

| High-Density Polyethylene (HDPE) | High tensile strength, rigidity, and impact resistance | Extreme kayaking conditions | Requires precise high-temperature control to prevent deformation |

| Low-Density Polyethylene (LDPE) | Reduced strength, more flexibility | Recreational use and low-cost market | Lower temperature profiles, economical production |

| Middle-Density Polyethylene (MDPE) | Balanced strength and flexibility | General boating activities | Moderate temperature control for versatile manufacturing |

Kayak manufacturing process involves choosing the right polyethylene and molding it carefully. Whether facing rapids or floating peacefully, the kayak’s material and build determine its performance and life. It blends technology, art, and science. And you, the kayaker, get to enjoy the result of this complex process.

Which Is Better? Kayak Manufacturing: Rotomolding Vs. Blow Molding!

Rotomoulded kayak manufacturing

Kayak Materials: From Density to Performance

For kayak lovers, choosing the right material is key to a great time on the water. You can pick from HDPE for extreme kayaking, which offers both strength and flexibility. Or choose affordable LDPE kayaks if you’re just starting out and watching your budget.

Exploring the Strength and Rigidity of HDPE Kayaks

HDPE kayaks excel in tough marine conditions. Their strong molecular build makes them perfect for rough white water or big sea waves. These kayaks stay in shape and keep you safe and reliable, which is critical for lovers of extreme kayaking.

MDPE: Balancing Cost and Performance for Kayakers

For those who paddle in calmer waters, MDPE kayak benefits are worth noticing. While not as strong as HDPE, MDPE is more budget-friendly without a big compromise on quality. It’s the middle ground for kayak enthusiasts who want a dependable option without going to the extremes.

LDPE Kayaks: Accessibility and Affordability Considerations

Starting in kayaking can seem hard with high costs. affordable LDPE kayaks help beginners get into the sport without spending a lot. But, be ready for some drawbacks like less impact resistance and a shorter lifespan. Still, they are a great choice for many newcomers.

| Kayak Material | Key Applications | Strength & Rigidity | Cost | Long-Term Durability |

|---|---|---|---|---|

| HDPE | Extreme Kayaking (White Water, Sea Kayaking) | High | Higher | Excellent |

| MDPE | Recreational Use, Day Trips | Moderate | Medium | Good |

| LDPE | Casual Paddling, Beginners | Lower | Lower | Adequate |

Advanced Kayak Manufacturing: Beyond Basic Plastics

The search for the perfect kayak is pushing manufacturing forward. We are moving beyond basic methods to advanced techniques. The industry now uses multi-layer structures and composite materials. These offer benefits and challenges for kayakers.

One-Layer Versus Multi-Layer Kayak Structures

One-layer kayaks made from polyethylene were durable for various conditions. Yet, multi-layer kayaks are a big step up. They balance weight and sturdiness for a better experience. The industry now prefers multi-layer designs for serious paddlers.

The Science Behind 3-Layer Sandwich Construction for Kayaks

The 3-layer sandwich construction is a breakthrough in kayak design. It uses an outer polyethylene layer, a middle foam layer, and a smooth inner layer. This offers lightness, rigidity, and durability. Precise temperature control during manufacturing is key for optimal kayak performance.

PE vs. Composite: A Battle of Weights and Traits

The kayak material choice often boils down to composite versus polyethylene. Polyethylene is durable and easy to repair but can deform. Composite kayaks, made from materials like fiberglass, are lighter and perform better. However, they cost more and might be harder to handle and repair.

Your choice depends on what you plan to do, your durability needs, and your budget. Whether you’re into casual lake paddling or adventurous ocean outings, knowing about advanced kayak manufacturing helps. It guides you to the right kayak for your adventures.

Choosing the Best Material for Your Paddling Style

When picking a kayak, the material is key for a great water experience. Whether you like calm trips or fast-paced adventures, the kayak’s make-up is crucial. Understanding eco-friendly options and repair needs helps in choosing the right kayak.

Your paddling goals, be it for fun or competition, deeply affect your choice.

Recreational Versus Performance-Driven Material Choices

If you paddle for fun, caring more about enjoying your time and saving money, durability matters. One-layer polyethylene (PE) kayaks offer both toughness and affordability. They’re perfect for peaceful water trips without breaking the bank.

For those chasing performance, aiming to navigate waters quickly, choices expand. Three-layer PE or composite materials are better. They focus on top hydrodynamic efficiency, giving the stiffness and lightness you need for speed.

Eco-Friendly Aspects of Kayak Construction Materials

Eco-conscious paddlers value green construction. Polyethylene is popular because it’s recyclable, reducing environmental harm. But, composite kayaks, while high-performance, aren’t as eco-friendly. They pose disposal problems.

Repair Considerations: The Longevity of Your Kayak

Kayak repairability is vital for its lifespan. One-layer PE kayaks are easier to fix, allowing for DIY repairs. Composite kayaks might need a pro, adding costs and maintenance complications. A balance between durability and repair ease can make your kayak last longer and simplify care.

| Material | Paddling Style | Eco-Friendliness | Repairability |

|---|---|---|---|

| One-layer PE | Recreational | High (Recyclable) | High |

| Three-layer PE | Performance | High (Recyclable) | Moderate |

| Composite | High Performance | Low | Low (Professional repair needed) |

Conclusion

Choosing the right material for your kayak plays a big role in your kayaking fun. High-density polyethylene (HDPE) kayaks are tough. They’re made for rough conditions. On the other hand, low-density polyethylene (LDPE) lets more people enjoy kayaking. When you pick a kayak, you’re picking a buddy for your adventures. Each one offers different benefits for your time on the water.

If you’re looking for something in between, consider medium-density polyethylene (MDPE). These kayaks meet the needs of those watching their budget and those who want good performance. The latest in kayak tech, like multi-layer PE and sophisticated composites, takes your kayaking to new levels. They offer great performance and easier handling. But remember, keeping our waters clean is also key. More kayakers now want boats that won’t harm the environment. This shows a shift towards enjoying kayaking without hurting our planet.

Choosing your kayak means thinking about what matters to you. Find one that suits your kayaking style and respects nature. It should support your goals and help keep our waters clean. Whether you’re enjoying calm lakes or tackling fast rivers, your kayak’s material matters. It’s the base of many great kayaking trips ahead.

FAQ

What are the best materials for kayak construction?

The top material for a kayak varies by use and needs. Polyethylene (PE) stands out for its toughness and is great for making kayaks. High-density polyethylene (HDPE) works best under tough conditions. MDPE and LDPE balance affordability with performance. For those seeking a lighter option with top-notch performance, materials like fiberglass, Kevlar, or graphite are ideal.

How does the kayak manufacturing process work?

Making a kayak usually involves rotational molding. This means polyethylene powder gets poured into a heated, rotating mold. As the mold spins, the plastic melts and coats it evenly. After cooling, the kayak has its shape. Keeping the right temperature is key for the kayak’s strength and look. Some advanced methods use multi-layer construction or composite materials.

What are the advantages of kayaks made from HDPE?

HDPE kayaks are very strong and can handle big impacts, perfect for rough kayaking. They also stand up well against UV rays and extreme temperatures. This means they last longer.

Why would someone choose an MDPE kayak?

Choosing an MDPE kayak offers a good mix of price and quality. They’re tough enough for casual use but not as pricey as other types. This makes them a favorite among many kayakers.

Are LDPE kayaks a good investment?

LDPE kayaks are the wallet-friendly choice for beginners. But they’re not as strong, which may affect how long they last. It’s important to think about this when on a budget.

What’s the difference between one-layer and multi-layer kayak construction?

One-layer construction means the kayak is made of a single material layer, making it robust but heavy. Multi-layer uses a 3-layer tech for a light, stiff, and warm kayak, boosting its performance.

How do composite kayaks compare to PE kayaks?

Composite kayaks, using fiberglass, Kevlar, or graphite, are light and stiff. This makes them move better in water but they need careful handling. They’re pricier but seen as high-end choices compared to PE kayaks, which are tougher and easier to fix.

What should I consider when choosing a kayak material for a specific paddling style?

Think about what kind of kayaking you’ll do. For leisure, polyethylene is durable and more affordable. For sports, lighter, stiffer kayaks work best. Also consider the material’s environmental impact and how easy it is to fix.

Are repair considerations important when selecting kayak materials?

Yes, considering how easy it is to repair a kayak is crucial. Polyethylene kayaks, especially one-layer types, are simpler to fix. This can matter a lot for costs over time. Composite kayaks require more expertise to repair, which could mean more expenses.

How do eco-friendly aspects factor into kayak material selection?

Eco-conscious kayakers look at the full life impact of a kayak’s material. Polyethylene can be recycled, which might appeal to those wanting to reduce their environmental footprint. Composites are harder to recycle, making them less attractive for eco-focused choices.